So what do fabricators do?

At Brisbane Tank Manufacturing we’ve hand picked our awesome fabricators; some have been on the job for decades and some are just starting on their journey and this mentorship type environment here creates the best crew around.

Tank manufacturing involves the fabrication of various components and parts that are used in the production of tanks. These fabricators are skilled in creating different pieces that are essential for the functioning of tanks such as the vessels themselves but also key components such as valves, unions, entry manways and more.

They may work on individual pieces or create a complete set of components that are necessary for the construction of tanks. It’s a highly skilled job and one that demands meticulous detail plus the right attitude that you’ve always got to have an eye on the results being absolutely 100% up to standard and spec.

Time To Plan

Our fabricators start the day with either sitting with our brief and quote team so we can as a group of experts discuss and plan out what each unique project and requirements are. Apart from having the expertise our crew have to be great communicators and strategists.

There also has to be genuine respect across the team so everyone is heard and everyone knows what their specific task and milestones are. At our team product design meetings we all contribute and this level of expertise allows participants to scope out the blue print of the each project and how the project is going to be executed.

What happens next?

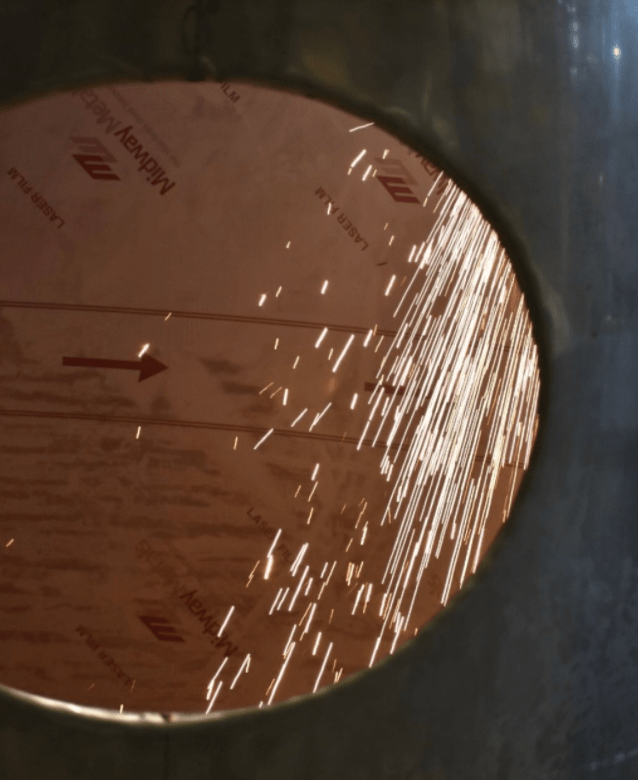

After design comes the cutting part.

When it comes to manufacturing tanks, as you can imagine precision is crucial. We have a number of tools to assist with the cutting including laser cutting, mechanical shearing, and water jet cutting. All of these techniques ensure accurate and clean cuts. These meet the strict tolerances required for tank manufacturing. You have to know what you’re doing right through the tank manufacturing project and selecting the appropriate cutting method is essential to ensure the quality and integrity of the metal components used in tank production.

Forming The Tank Is Up Next

Then we’re into the forming part of the project where the tanks start to come together. The process of tank manufacturing involves various techniques such as folding, bending, stamping, punching holes, and machining to achieve the desired shape and configuration that is set out in the blue prints.

There is never one size fits all when it comes to tank manufacturing so each tank is handled and formed with kid gloves.

Finally it’s time for assembling the tank

The process of tank manufacturing involves shaping metal parts into the desired form and then assembling them to create the final product. The individual parts are fitted together and secured with clamps before being permanently joined. This joining process can be done through bonding, screwing, riveting, or most commonly, welding.

At the completion of each tank manufacturing project, our team experiences a real sense of pride. They have been involved in every step of the process, from the beginning to the end.

This level of involvement allows them to take ownership of the project, which is a powerful feeling. Additionally, they can take credit for the outstanding results achieved. There is nothing that fills us with more pride than the successful completion of each project. When it’s time to talk tanks, come and talk to us.