In the world of construction and road development, efficiency is paramount.

One crucial component in this arena is the bitumen mixing tank which by the way Brisbane Tank Manufacturing has had plenty of experience in creating for operations across Australia.

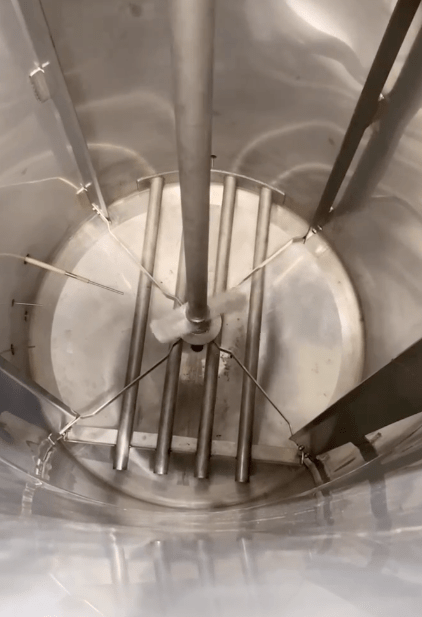

The bitumen mixing tank is a vital apparatus in the production of asphalt. Today, we’ll explore the innovation of the 5000 litre bitumen mixing tank equipped with not one, not two, but four heating elements, revolutionising the way we approach asphalt production.

Unveiling the 5000 Litre Bitumen Mixing Tank

Traditionally, bitumen mixing tanks have relied on a single or dual heating element setup to maintain the ideal temperature for the bitumen.

However, manufacturers like our awesome crew at BTM have recognised the need for greater efficiency and consistency in asphalt production. Thus, the introduction of the 5000 litre bitumen mixing tank with four heating elements marks a significant improvement in efficiencies in this field.

Enhanced Heating Capacity

One of the primary advantages of incorporating four heating elements into the bitumen mixing tank is the enhanced heating capacity.

With multiple heating points strategically positioned throughout the tank, heat distribution becomes more uniform, ensuring thorough heating of the bitumen. This not only accelerates the heating process but also minimises the risk of uneven temperature zones within the tank, resulting in a more consistent final product.

Improved Temperature Control

Temperature control is critical in bitumen mixing to achieve the desired viscosity and ensure optimal asphalt quality.

By integrating four heating elements, operators gain a lot more control over the temperature settings, allowing for precise adjustments according to specific production requirements. Whether it's maintaining a steady temperature during mixing or quickly reaching the desired heat for efficient production, the enhanced temperature control offered by the quad-heating element design proves invaluable.

Reduced Downtime and Increased Productivity

In construction projects where time is of the essence, minimising downtime is crucial. The utilisation of a 5000 litre bitumen mixing tank with four heating elements translates to reduced heating times, thereby streamlining the production process and boosting overall productivity.

Additionally, the improved efficiency in maintaining consistent temperatures reduces the need for frequent interruptions and adjustments, further enhancing workflow continuity.

Energy Efficiency and Cost Savings

Efficiency goes hand in hand with sustainability and cost effectiveness. The incorporation of four heating elements in the bitumen mixing tank not only optimises energy utilisation but also contributes to significant cost savings over time. By evenly distributing heat and minimising heat loss, less energy is wasted, leading to lower operational costs and a reduced environmental footprint.

That’s what we call a win-win for both businesses and the planet.

Innovation drives progress and Brisbane Tank Manufacturing get really excited about that.

The introduction of the 5000 litre bitumen mixing tank with four heating elements showcases this within the construction industry.

By leveraging enhanced heating capacity, improved temperature control, reduced downtime, and increased energy efficiency, this cutting-edge equipment sets a new standard for asphalt production efficiency and quality.

As we continue to push the boundaries of technology and engineering, such advancements pave the way for a more sustainable and prosperous future in infrastructure development. If you’d like to find out more then let’s talk tanks!