Pressure vessels are essential components in industries ranging from oil and gas to pharmaceuticals, power generation and chemical processing.

What are they designed to do?

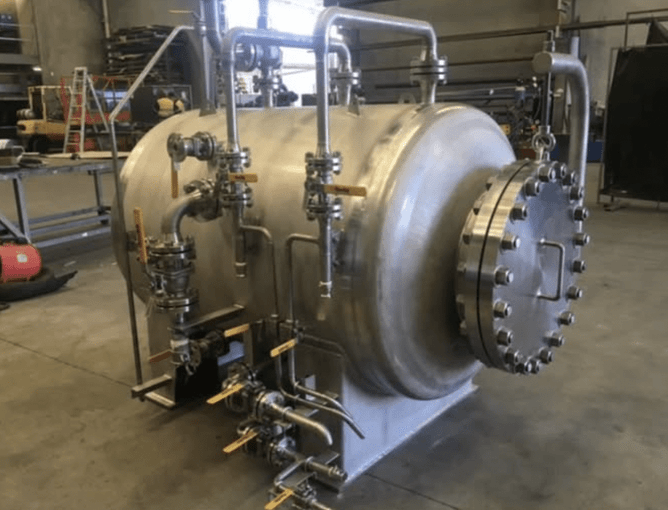

These specialised containers are designed to withstand high pressure environments while ensuring safety and functionality. Among the latest innovations in pressure vessel design, the highly detailed pressure vessel with a davit arm for manway door removal stands out.

This system, paired with 316 stainless steel and certified pressurised piping is engineered for both performance and safety ensuring that maintenance operations are smooth, efficient and safe.

In this blog post we will explore the advanced features of these pressure vessels, the benefits of using 316 stainless steel and how the addition of a davit arm enhances operational efficiency. We’ll also touch on certified pressurised piping and its role in maintaining safety standards.

What is a Pressure Vessel?

A pressure vessel is a container designed to hold gases or liquids at high pressures, far beyond atmospheric levels. These vessels must be constructed to rigorous standards to ensure safety, durability and compliance with industry regulations. Common applications of pressure vessels include boilers, gas cylinders, steam separators and storage tanks for chemicals, gases and oils.

Pressure vessels often feature manway doors which are large access openings that allow operators to inspect, maintain and clean the interior. These manway doors are typically secured with bolts, but the challenge comes when they need to be removed or replaced. This is where the davit arm system plays a vital role in ensuring safety and ease of access.

The Role of a Davit Arm in Manway Door Removal

A davit arm is a mechanical lifting device designed to assist in the removal and replacement of heavy equipment, in this case, the manway door.

Here are some key features of the davit arm

Efficient Lifting: The davit arm makes it possible to safely remove heavy manway doors without risking operator injury or damaging the door. It helps to lift and maneouver the door with precision.

Safety: Removing manway doors can be a delicate process, especially under high pressure conditions. A davit arm allows for the precise control of the door’s removal, reducing the chances of accidents.

Durability: Made from robust materials, the davit arm can handle the considerable weight and stress associated with removing and reinstalling heavy pressure vessel doors.

Ease of Use: With a davit arm, operators do not need to rely on manual labour or cumbersome tools to remove a manway door, increasing both speed and safety during maintenance activities.

Why Use 316 Stainless Steel for Pressure Vessels?

When it comes to pressure vessel construction, 316 stainless steel is a premium material choice. This high grade alloy contains chromium, nickel and molybdenum which gives it superior resistance to corrosion, especially in aggressive environments like marine, chemical and pharmaceutical applications.

Advantages of 316 Stainless Steel:

Corrosion Resistance: 316 stainless steel is highly resistant to chlorides, acids and other corrosive substances, making it the ideal material for pressure vessels that are exposed to harsh environments. This ensures that your pressure vessel maintains its structural integrity even in the most extreme conditions.

Strength and Durability: The added molybdenum in 316 stainless steel increases its strength making it ideal for withstanding high pressure applications. It also ensures the pressure vessel maintains its shape and performance over time.

Longevity: 316 stainless steel offers long term durability, reducing the need for frequent replacements or repairs and extending the operational lifespan of your pressure vessel.

Hygienic Properties: In industries such as food, beverage and pharmaceuticals, 316 stainless steel is an ideal choice due to its smooth surface, which minimises the potential for bacterial growth and makes cleaning and sterilisation more efficient.

Certified Pressurised Piping for Safety and Compliance

Pressure vessels are only as safe as their supporting systems and one of the most critical systems is the piping that delivers the pressurised media into and out of the vessel.

Certified pressurised piping ensures that all pipes, fittings, valves and other components are capable of safely handling the operational pressures and any fluctuations that may occur. Typically, certified pressurised piping is subject to strict inspections and testing to meet industry standards.

The Importance of Regular Maintenance and Inspections

While 316 stainless steel, davit arms and certified piping systems significantly improve the overall performance and safety of pressure vessels, it’s important to remember that regular maintenance and inspections are necessary to keep everything running smoothly.

Inspection of Manway Doors: Regularly checking the integrity of the manway doors, including hinges, gaskets and the davit arm mechanism, ensures that the system remains easy to operate and safe for workers.

Pressure Vessel and Piping Inspections: Pressure vessels and piping systems should be inspected for corrosion, wear and any signs of stress fractures. This is particularly important in environments where there are high temperatures, aggressive chemicals or fluctuating pressures.

Safety Protocols: Establishing safety protocols for manway door removal, including using proper lifting techniques with the davit arm and wearing appropriate protective equipment ensures the safety of personnel.

Highly detailed pressure vessels with a davit arm for manway door removal, constructed from 316 stainless steel and equipped with certified pressurised piping, represent the cutting edge of pressure vessel technology. As industries continue to push the limits of technology and innovation, these pressure vessels will remain a cornerstone of industrial processes that require high pressure, precision and safety.

Want to find out more? Talk to the team at Brisbane Tank Manufacturing today