When it comes to industrial storage solutions, selecting the right material for your tank is critical. While stainless steel often steals the spotlight, mild steel tanks remain a reliable, cost effective, and widely used option across many industries.

But what exactly is a mild steel tank? Who uses them? And why does professional fabrication matter so much?

Let’s break it down.

What Is a Mild Steel Tank?

A mild steel tank is a storage or process vessel fabricated using mild steel also known as low carbon steel. This type of steel contains a small percentage of carbon (typically 0.05% to 0.25%) which gives it key advantages:

High strength and durability

Excellent weldability

Cost effectiveness compared to other metals

Flexibility in fabrication and forming

Mild steel tanks can be manufactured in a variety of shapes and sizes; vertical or horizontal, cylindrical or rectangular and are suitable for both atmospheric and low pressure applications.

What Industries Use Mild Steel Tanks?

Mild steel tanks are used in industries where corrosion resistance is not the primary concern or where internal linings or coatings can be applied for added protection. Some key sectors include:

1. Water and Wastewater Treatment

Ideal for storing raw or treated water, sewage and other non corrosive liquids.

Can be internally coated or lined to handle varying pH levels.

2. Agriculture

Used for liquid fertilisers, water, molasses and slurry storage.

Cost effective for large scale farming operations.

3. Mining and Resources

Suitable for process water, slurry, diesel and chemical mixing tanks.

Often fabricated for rugged onsite environments.

4. Construction and Infrastructure

Commonly used for site water storage, concrete batching and temporary fuel storage.

5. Manufacturing and Industrial Processing

Ideal for oil, lubricants and process fluids.

Easily fabricated to meet bespoke process requirements.

Why Choose Mild Steel?

While it doesn’t offer the corrosion resistance of stainless steel, mild steel has significant benefits in the right application:

Lower Material Cost – Great for large volume tanks where stainless steel would be cost prohibitive.

High Strength to Weight Ratio – Withstands structural loads and pressure with appropriate wall thickness.

Customisation Flexibility – Can be fabricated, rolled and welded into virtually any configuration.

Easy to Repair and Maintain – Weldable and adaptable for modifications or refurbishments.

For environments with corrosive substances or harsh exposure, protective internal coatings or linings (like epoxy or rubber) are typically applied to increase durability.

Why Professional Manufacturing Matters

Regardless of material, a storage tank is only as good as its fabrication. Choosing a professional manufacturer like Brisbane Tank Manufacturing ensures:

Precision Engineering

Our in house engineers design to exact specifications and relevant Australian Standards.

Quality Materials

We source certified mild steel with full traceability, ensuring long term performance.

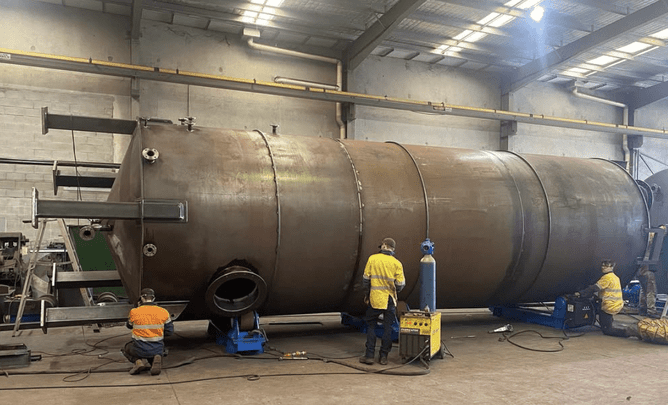

Expert Fabrication

Our skilled team delivers clean welds, structural integrity and expert fitting placement.

Safety and Compliance

All tanks are tested to meet safety codes and industry regulations – from AS1210 to API standards.

Turnkey SolutionsFrom design and fabrication to delivery and installation, we provide a full service experience.

Mild steel tanks remain a trusted solution for a wide range of industrial applications. When manufactured professionally, they offer outstanding performance, durability and value.

At Brisbane Tank Manufacturing we bring decades of experience, advanced capabilities and a commitment to excellence whether it’s mild steel, stainless steel or pressure rated vessels.

If you're looking for a reliable, high quality tank tailored to your needs, get in touch with the BTM team today. Let’s talk tanks!