Let’s talk tanks because let’s face it - it’s what we do best! It’s not just our job; it’s a bit of a slight obsession with us.

You have to be all over it when it comes to manufacturing tanks because there are so many purposes each tank has and so many different configurations we have to cater for.

From the type of job the tank has to do to the type of premises each tank has to be installed at; we have our finger on the pulse each and every project.

These next two blogs we’re going to explain a bit more around some of the different types of tanks; what they do and how we do it.

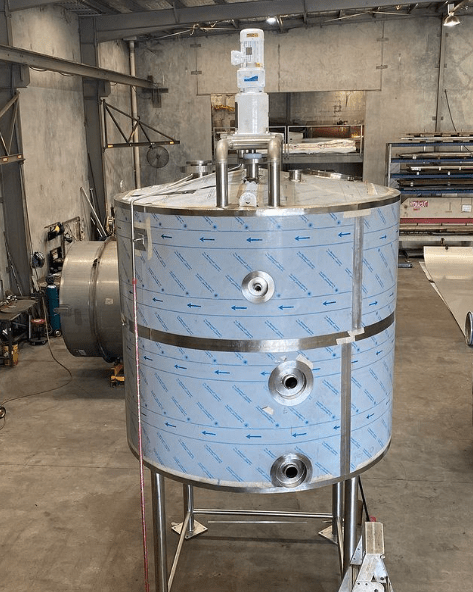

Mixing Tanks - What are they used for?

Mixing tanks are part of chemical processing and play an important role in creating new products by blending multiple liquid and other components together.

Think about how beer is crafted for example. You pull together key ingredients such as yeast, water, hops, barley and mix them all together but there is a process and procedure that is taking place to create the end product. A mixing tank is all part of this process.

These tanks are carefully designed and crafted with separate inputs for each component and output piping to transfer the mixture to the next phase of the process system.

Our team start by taking on a full scope or brief of works from our customers to find out more about every element of the mixing tanks e.g what it needs to do, what size it needs to be and where it’s going to be installed.

There’s a lot that goes on behind the scenes before we can even get started on manufacturing a mixing tank.

It doesn’t matter what sort of job these tanks need to perform be it pharmaceuticals, food and beverage, or industrial chemicals, mixing tanks are a crucial component in the production process. Each tank has to be up for the job and has to be on point when delivering on compliance too.

Brisbane Tank Manufacturing specialises in the production of mixing tanks, which can be customised to meet a whole range of specific needs.

We offer a variety of steel options and our tanks come in a range of sizes to suit any project. Whether you need a small tank for laboratory use or a large tank for industrial applications, we have the expertise to deliver a high-quality product that meets any requirements.

We pride ourselves on being your go to resource for top quality tank manufacturing, tank installation, tank maintenance and more. Find out more and let’s talk tanks!

Take a look at one of our more recent mixing tank projects. This 10,000 litre food grade mixing tank is heading to a beverage company who we know are going to be over the moon with their new addition. This mixing tank features dimple plates and a welded stainless steel outer case. What a pocket rocket of a tank!